Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Supplied By

- CASE Ingredients Functions

- CAS No.

- 30499-70-8

- EC No.

- 608-489-8

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Product Highlights

- Long pan life in humid conditions

- Wide range of diluents possible

- Good slip retention on polyethylene films

- Low retained solvents in laminates

- Product resistance on clear films

Applications & Uses

- Markets

- Applications

- Segments

- Applications

- Compatible Substrates & Surfaces

- Adhesive & Sealant End Applications

- Recommended Applications

- OPP/MOPP - OPP/LDPE

- MPET/LDPE - PET/LLDPE

- Coex/OPP - Coex/Coex

- Cast PA/LDPE - OPA/LDPE

- LDPE/LDPE - Aclar®/PVC

- Applications Procedure

Mixing Data

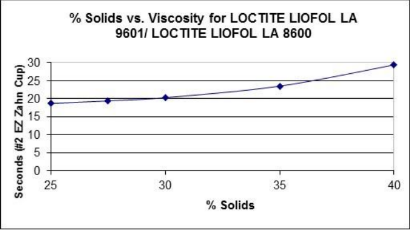

LOCTITE LIOFOL LA 8600 should be thoroughly mixed together in the ratio of 15:1 pbw prior to dilution to the recommended application solids content of 25-35%. Suitable diluents include ethanol, isopropanol, ethyl acetate and blends of these. The chart below may be used for reference and is typical for Loctite Liofol LA 9601/Loctite Liofol LA 8600 when diluted with ethanol. Determine the % running solids required:

Application Weight

The mixed adhesive should be applied to give dry coating weights of 1.0-1.5 lb/ream dry for unprinted or low ink coverage webs.

Drying Conditions

Air temperatures, volumes, and exhaust efficiencies in the drying tunnel should be sufficient to remove all the solvents from the coated web. Usually an exit web temperature of 120-150°F is sufficient. Higher nip temperatures will give higher clarity and bond strengths, but may increase curl in the laminate.

Nipping Conditions

A laminating nip temperature of 120-180°F will give good initial bonds with good clarity. Higher nip temperatures will increase initial bond and clarity, but may increase curl in the laminate.

Bond Strength

In general, green bonds will exceed 400 grams per inch and final bonds will be substantially higher except in those cases where coating anchorage or ink adhesion are limiting factors.

Clean Up

Wet and dry adhesive remnants and application equipment may be cleaned with ester or ketone solvents. This product is incompatible with isocyanate based urethane adhesives. The application station including anilox, pump and sump should be thoroughly cleaned when switching adhesive systems.

- Recommended Mixing Ratio

1 part by weight

Packaging & Availability

Storage & Handling

- Shelf Life

- 12 months

- Storage Conditions

- They should be held at normal warehousing temperatures and stored in the original, unopened containers.

- Containers of the adhesive or curing agent should not remain open for an extended period of time.

- Material from opened containers should be consumed within a short period.

- It is necessary to use all the adhesive, once the container is opened, unless there is means of purging the container with dry nitrogen.

- LOCTITE LIOFOL LA 8600 has a shelf life of 12 months